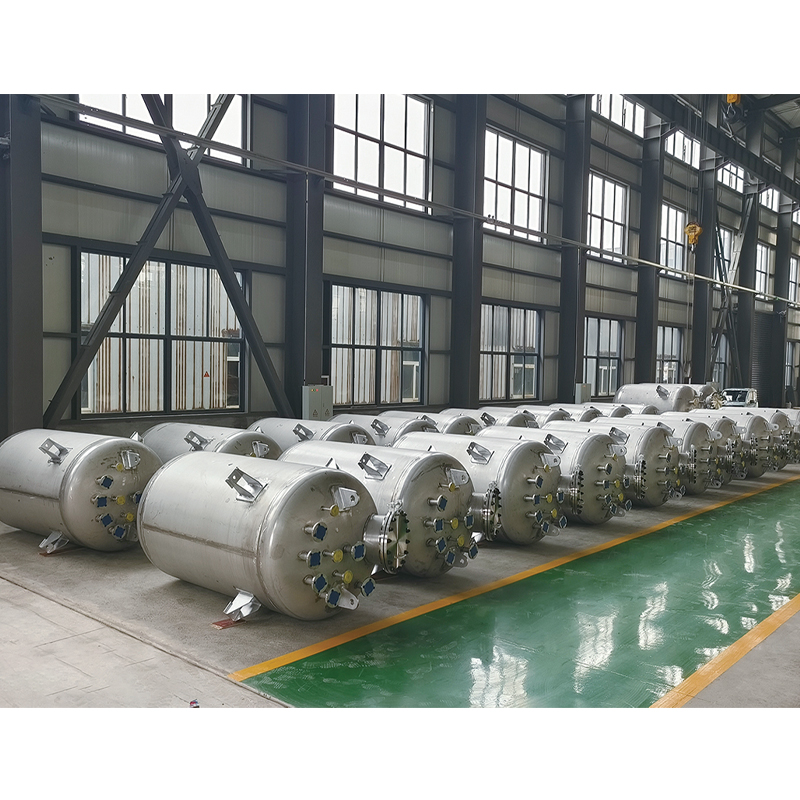

Stainless Steel Reactor

500L-50000L

After both parties discuss and finalize the technical solution and confirm the drawings, production begins.

Advantages and Applications of Stainless Steel Reactors

I. Core Advantages

1. Excellent Mechanical Properties

- High Strength: High pressure resistance (up to 10 MPa and above) and impact resistance make it suitable for vigorous mixing or high-pressure reactions.

- Wear Resistance: High surface hardness makes it less susceptible to abrasion by solid materials.

2. Excellent Corrosion Resistance

- Broad corrosion resistance: 304/316L stainless steel is resistant to weak acids, weak bases, organic solvents, and some strong acids (such as nitric acid).

- No Risk of Coating Peeling: Compared to glass-lined equipment, there is no risk of cracking or peeling of the enamel layer.

3. High Cleanliness and Hygiene

- Smooth Surface: Mirror polished (Ra ≤ 0.4 μm), it is unlikely to retain residual material and complies with GMP and FDA standards (mandatory requirements for the pharmaceutical and food industries).

- Suitable for Aseptic Environments: High-temperature sterilization (above 121°C) is possible, making it suitable for aseptic production.

4. Wide Temperature Adaptability

- High Temperature Resistance: Wide operating temperature range (-196°C to 800°C), supporting rapid temperature rise and fall (no risk of cracking enamel due to sudden temperature changes).

5. Easy Processing and Maintenance

- Weldable/modifiable for easy installation of interfaces (such as sensors and feed ports).

- Easy Maintenance: Surface damage can be repaired, and cleaning costs are low.

II. Main Applications

By Industry:

1. Pharmaceuticals and Bioengineering

- Aseptic Reactions: Synthesis and fermentation of vaccines, injectable solutions, and biological products.

- High-Purity Materials: Crystallization and purification of APIs.

2. Food and Beverages

- Sanitary Production: Fermentation and blending of dairy products, juices, and condiments.

- High-Temperature Sterilization: Sterilization of canned goods and sauces.

3. Fine Chemicals

- High Value-Added Products: Synthesis of fragrances, cosmetics, and electronic chemicals.

- High-Pressure Reactions: Hydrogenation and polymerization (such as polyethers and silicone oils).

4. New Materials and Research

- High-Temperature/High-Pressure Experiments: Nanomaterial Synthesis, Catalyst Research.

- Inert Environment Reactions: Reactions requiring argon/nitrogen protection.

By Process Type:

- High-Temperature/High-Pressure Reactions (e.g., hydrogenation, polymerization)

- Hygiene-Sensitive Processes (sterile preparations, food processing)

- Severe Mechanical Stress Scenarios (mixing of high-viscosity materials, reactions involving solid particles)

III. Selection Considerations

1. Material Selection

- General: 304 stainless steel (resistant to weakly corrosive media, low cost).

- High Corrosion Resistance Requirements: 316L stainless steel (Mo-containing, resistant to chlorides and organic acids).

- Special Environments: Duplex Steel (resistant to stress corrosion), Hastelloy Alloy (strong acid/high temperature).

2. Key Structural Design Considerations

- Sealing Type: Mechanical Seal (high pressure/vacuum) > Packing Seal (normal pressure).

- Agitation Type: Anchor/Screw Ribbon (high viscosity) > Turbine (mixing efficiency).

3. Avoid Use

- Strong acids containing chloride ions (such as hydrochloric acid): prone to pitting/stress corrosion cracking (requires titanium or plastic lining).

- Strong reducing acids (such as hydrofluoric acid): drastically increase the corrosion rate.

Stainless Steel Reactor Characteristics

Mechanical Shock Resistance: Excellent

High Pressure Adaptability: Excellent (10MPa+)

Summary

Stainless steel reactors are the preferred choice for applications requiring high hygiene, high pressure/high temperature, and no strong acid corrosion, such as pharmaceuticals, food, and fine chemicals. They are particularly indispensable in processes requiring mechanical strength, easy cleanability, and a sterile environment. When selecting a reactor, avoid media containing chloride ions and precisely match the material (316L/duplex steel) to the corrosion potential.